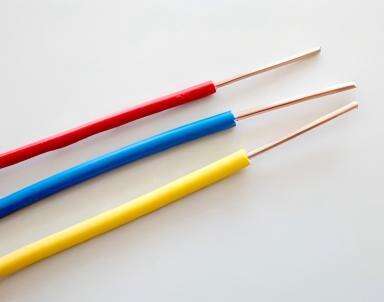

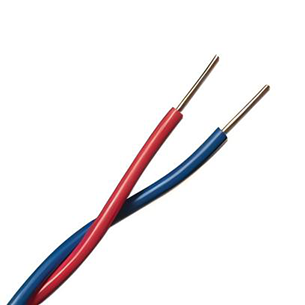

A filo aeneo nudo ad fasciculum bifilarem igne resistibilem

Ab anno 1990, Jiangsu Jiacheng Technology Co., Ltd. se dedicavit industriae fabricandi funes et cablum. Sumus societas perita quae conficit varios generis machinas ad fabricandum filos et cabla, sicut machinae trahentes, torquentes, extrudentes, volventes et involventes, intortantes, molientes et stanneantes, aliaque machinae conexas ad faciendum filos et cabla.

Nuper, nostra societas feliciter adiit conventionem cooperationis cum cliente in Emiratis Arabum Unitis et tradidit planum integrum pro productione cablum ignis resistens cum duobus nucleis area 1.5-2.5 quadrata. In processu acceptationis, clientus multum laudavit mechanicam operationem, qualitatem et varias servitios post venditionem nostrae societatis, et sperat ulteriorem cooperationem cum Technologia Jiacheng in futuro.

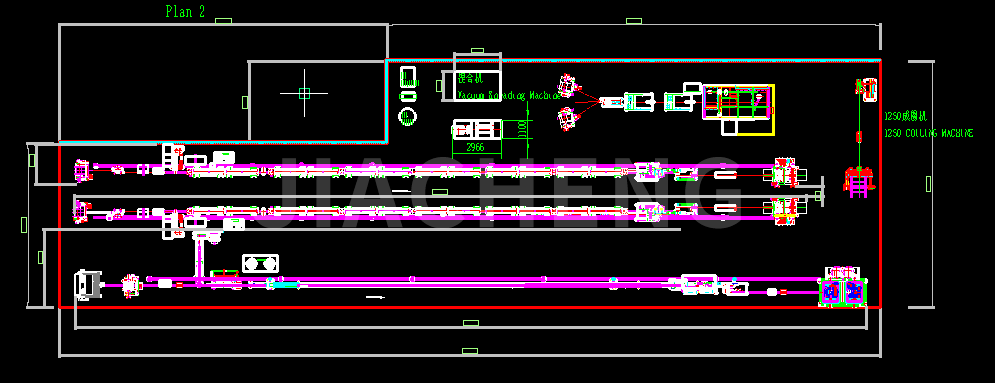

Hoc planum traditum est uni ex nostris clientibus ex Emiratis Arabum Unitis. Percurrimus per quattuor menses a contractibus ordinibus cum clientibus, completa productione, acceptatione clientium, arrangemente transportis container, arrangemente ingeniorum pro debuggage, usque ad finaliter attingendum normalem productionem pro clientibus.

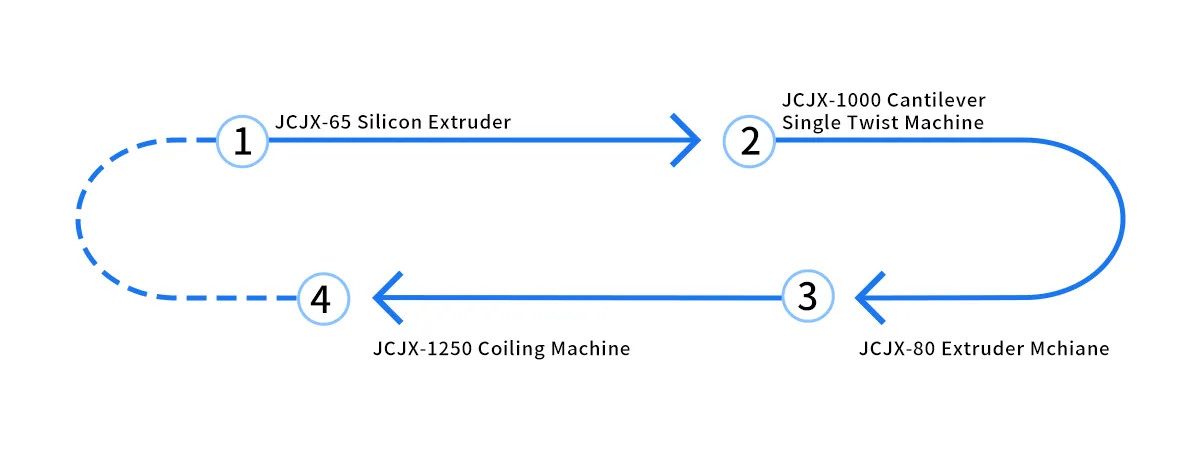

Sunt in toto quattuor lineae productionis, et detailia sunt sicut sequitur:

1. JCJX-65 Extruder Silicia Extrusion nucleus filii

2. JCJX-1000 Machina Simplex Cantilever Torquetion Torquentio nucleus filii

3.JCJX-80 Extruder Extrusio tegumenti

4.JCJX-1250 Machina Convolvens Convolutio

Delineationes planningae fabricae clientis:

JCJX-65 Extrusor Siliciae

Applicatur ad omnes generas funiculorum silicium altae temperaturae et vaginas altae temperaturae.

1.PLC + Tela tactilis control , parametrum totius lineae productionis adjustio et monitorium.

2.Rubrum siliconicum usum screw et barili, crosshead et dies ut interioris vulcanizationem praeventiant.

3.Rubrum siliconicum usum evitando adjustio die-head, systema refrigerationis aquae automaticum contaol vel manualem control.

4.Cum systema praecisionis testing feedback ut accuratam diametrum fili securus sit ita ut costum reducat.

| exemplum | JCJX-45 | JCJX-70 | JCJX-90 | JCJX-120 |

| Virtus principalis machinae (kw) | 11 | 22 | 37 | 45 |

| Capacitas extrusionis (kg/h) | 30 | 80 | 135 | 260 |

| Diametrus helicis (mm) | φ45 | φ70 | φ90 | φ120 |

| RATIO SCROFAE L\/D | 12:1 | 14:1 | 14:1 | 14:1 |

| MATERIA DIMENSIONIS ROTULI (mm) | φ300-400 | φ400-630 | φ400-630 | φ1000-1200 |

| DIMENSIONES CONDUCTORIS (mm) | φ0.2-3.0 | φ1.5-6.0 | φ2.1-10 | φ5.0-15 |

| Dimensiones terminadas de cable (mm) | φ0.8-5.0 | φ1.8-8.0 | φ3.0-12 | φ8.0-20 |

| Longitudo vasculi vulcanizationis (m) | 12 | 16 | 24 | 24 |

| Vires calefaciendi | Sectio 36kw | Sectio 48kw | Sectio 72kw | Sectio 84kw |

| Motor trahendi (kw) | 2.2 | 4 | 7.5 | 11 |

| Velocitas productionis (m/min) | 10-200 | 10-200 | 4-40 | 4-40 |

| Materiam accipientes dimensiones bobbin (mm) | φ400-500 | φ400-630 | φ1250-1600 | φ1250-2000 |

JCJX-1000 Machina Simplex Torquens Brachii Unici

Ad omnium generum funiculi et involucrum usus et item ad omnium generum conductorem mollem et funiculum computatricis, funiculum caucci et funiculum controlis ut KVVRP, KVVR, RVV, KVV.

1) Maior stabilitas, altior efficentia productionis, infimus sonitus et facilis ad operationem.

2) Potes torquere et funiculum et filum cupri.

3) Torquens et involvens simul.

| Exemplum | JCJX-630 | JCJX-800 | JCJX-1000 | JCJX-1250 |

| Diametrum bobinae praeparationis (mm) | φ400-Φ500-Φ630 | |||

| Diametrum bobbinæ receptivæ (mm) | φ630 | φ800 | φ1000 | φ1250 |

| Conveniens diametrum fili (mm) | φ0.6-3.0 | φ1.0-5.0 | ||

| Vis motoris principalis(kw) | 11 | 15 | 15 | 20 |

| Maximus diametrum dispositionis (mm) | φ15 | φ20 | φ25 | φ30 |

| Torsio pitch(mm) | 20-200 | 30-300 | 30-350 | 30-350 |

| Numerus rotationis(r/min) | 1000 | 800 | 600 | 550 |

| Receptura tensio | Pneumatica tensio | |||

| Stilus transeundi | Regulatio continua, secundum velocitatem rotationis fusorum et motum reciprocantem | |||

| Intervallum transeundi(mm) | 2-12 | 3-20 | 3-30 | 3-30 |

| Directio torquens | Directio S aut Z liber descriptio | |||

| Genus involvens | Involventes filum centrali vel laterali involvente | |||

JCJX-80 Extrusor

Utendum est ad insulationem fili et cabli cum PVC, LDPE, NYLON, TPU. Item potest esse aequiparatum cum triple co-extrution crosshead et bini strati.

1.Compositio lineae productionis: pay off, machina principalis, armarium principale, fossa fixa, fossa mobilis, accumulator, tractio, take-up, spark tester.

2.Partes optionales: active pay of, praefoculator, powder machine, diameter-testing laser gauge, LSZH screw, single et dual bobbin take-up, coiling et wrapping machine.

3.Caracteristica: designatio precisa rotamatis, durabilis, non viscosus, non ablatus chrome, celeriter mutat colorem, cum magna capacitate, alta qualitas, concentricitas fili plus quam 90%, cum alta praecisione ±0.03. Cum touch screen+PLC control, facilis operatio, magis homogeneus.

| Typus | JCJX-30 | JCJX-40 | JCJX-50 | JCJX-60 | JCJX-70 | JCJX-80 | JCJX-90 |

| Diametros Fusi (mm) | ø30 | ø40 | ø50 | ø60 | ø70 | ø80 | ø90 |

| RATIO SCROFAE L\/D | 25:1 | 25:1 | 25:1 | 25:1 | 25:1 | 25:1 | 25:1 |

| Capacitas Extrusionis (kg/h) PVC | 25 | 40 | 80 | 100 | 130 | 200 | 240 |

| Capacitas Extrusionis (kg/h) LDPE | 16 | 20 | 40 | 53 | 86 | 122 | 133 |

| Capacitas Extrusionis (kg/h) PP | 13 | 17 | 34 | 41 | 68 | 96 | 124 |

| Potentia motoris principalis | 5.5 | 7.5 | 11 | 18.5 | 22-37 | 30-55 | 37-75 |

| Summa potentia | 21 | 24 | 28 | 42 | 50 | 65 | 75-113 |

| Diametrus Finitus (mm) | 0.2-1 | 0.4-3 | 0.8-5 | 1-8 | 2-12 | 3-25 | 5-35 |

| MATERIA DIMENSIONIS ROTULI (mm) | 300/400 | 300/500 | 400/630 | 500/630 | 500/630 | 500/630 | 630/800 |

| Vires Solvendi | 2.2 | 3.7 | 3.7 | 3.7 | 3.7 | 5.5/7.5 | 7.5/11 |

| Genus Unitatis Tractandi | Capastan | Capastan | Capastan | Capastan | Capastan | Capastan Caterpillar | Capastan Caterpillar |

| Vires Machinae Tractus | 1.5 | 2.2 | 2.2 | 3.7 | 3.7 | 5.5 | 5.5 |

| Longitudo Accumulatoris (m) | 220 | 220 | 220 | 220 | 220 | 220 | 220 |

| Machina Receptus Dimensus (mm) | 400/500 | 400/630 | 400/630 | 500/630 | 630/800 | 800/1000 | 630/1250 |

| Vires Assumptionis | 2.2 | 2.2 | 2.2 | 2.2 | 3.7 | 3.7 | 5.5 |

| Velocitas Lineae (m/min) | 10-650 | 10-650 | 10-650 | 10-650 | 10-500 | 10-350 | 10-250 |

| Dimensiones(m) (L*W*H) | 20*1.5*2.1 | 20*1.6*2.1 | 20*1.7*2.1 | 20*2.5*2.1 | 25*2.5*2.1 | 25*3.2*2.1 | 30*3.6*2.1 |

| Pondus (T) | 5 | 6 | 8 | 8 | 8.5 | 7-9 | 9-12 |

JCJX-1250 Machina Convolvens

Utile est praecipue ad volutas longas filorum aut funicum in spira revolvendas, ut subsequens conglutinatio, translatio et usus facile fiant.

Proprietas:

1. Tensio automatica potest controllare unitatem solvendi, fili disponuntur perfecte in bombycinis.;

2. Uti solvendo set automato, solvitur filum ordinate.

3. Alta efficiencia, communiter producit 700 in 8 horis, triplicat elevatio.

| Exemplum | φ630mm | φ1250mm | φ1250-Φ1600mm |

| Applicabilis rangus fili | 0.5-6mm2 | 10-70mm2 | 10-240mm2 |

| Transtendere tensionem | Automate | ||

| Celeritas motoris principalis | 0-600 r/min | 0-300 r/min | 0-300 r/min |

| Typus bobbinae onerantis | Lever-type | Electric type | Electric type |

| Model bibbinarum solvendarum | φ400-630mm | φ800-1250mm | φ1000-1600mm |

| Modelus perforandi | Diametrus exterior ≤320mm Diametrus interior 120mm Largitudo 30-100mm | Diametrus exterior ≤600mm Diametrus interior 200-300mm Largitudo 60-150mm 150-200mm | 50-250 |

| Potentia | 2.2KW | 3kw | 4kw |

| Structura computatoris metrorum | Genus pressionis rotulae | Typus bini rotae cum pressione aeris | Typus bini rotae cum pressione aeris |

| Genus inductionis / Praecisio mensurae | Codex rotatorius / 0.5% | Codex rotatorius / 0.5% | Codex rotatorius / 0.5% |