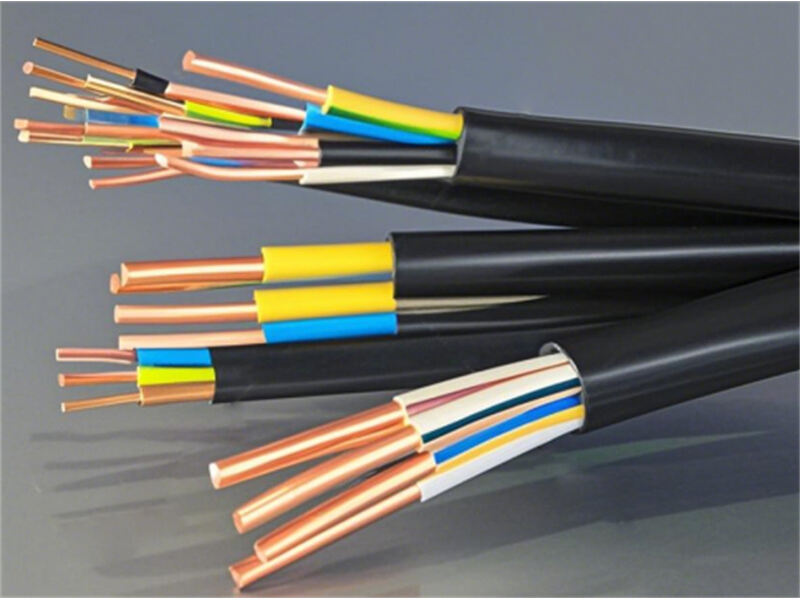

Uzbekistan, ut centrum energeticum in Asia Centrali, accelerat modernizationem retelectricum suum et progressum projectorum novae energiae. Anno 2024, nostra societas contraxit pactum cum cliente in Uzbekistano de integro designio machinarum ad conficiendum filos 0.5-6mm² cum 2-5 nucleis et cables planos 2 * 1.5mm², complectens omnem processum designii, fabricationis, installationis et formationis personarum.

Post praeparatoriam investigationem, conformationem planorum, communicationem et modificationem, contractus signationem, machinamentorum productionem, machinarum traductionem, ingeniorum mittendum ad installationem et probandum, totus processus quattuor menses sumpsit. Nunc, fabbrica clientis coepit producere, et persona responsabilis pro coordinatione fabbricae laudibus altis machinamenta Jiacheng praebuit, dicens quod cum Jiacheng in futuro cooperabuntur.

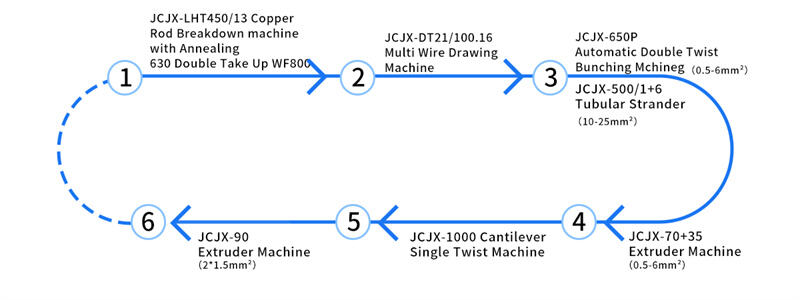

Universus designatio machinarum est haec:

1.LHT450/13 Cuprum Virgula Fractura Machina Cum Calenditione Deducendo a 8mm filo cupri ad 1.2-3.5mm

2.JCJX-DT21/100.16 Multi Filum Deductio Machina Faciens 0.15-0.5mm filos tenuissimos

3.JCJX-650P Automatica Duplex Tortio Concretio Machina Torsionando 19-84 fila ad producendum mollia torta conductores 0.5-6mm² quadratis metris

4.JCJX-70+35 Machina Extrusoria Isolatio extrusio pro filis quadratis 0.5-6

5.JCJX-1000 Macchina Simplici Torchio Filati 2-5 nucleorum filis isolatis

6.JCJX-90 Machina Extrusoria Praebet tunicam protectivam pro 2-5 nucleo fune et filo plano 2 * 1.5mm2

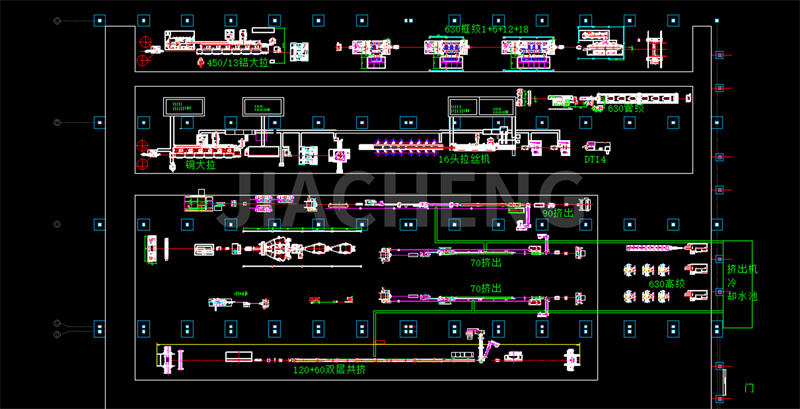

Delineationes planningae fabricae clientis:

LHT450\/13 Machina Fracturæ Virgae Cupri cum Annealing

JCJX-LHT450/13 macchina celeris cupri virgae disruptio est ad trahendum ∮8mm cuprum virgam ordinariam ad ∮1.2-3.5mm filum cupri molle. Rotae tractoriae in linea disponuntur ut possint operari continuo cum alta velocitate tractionis. Partes mechanicarum et electrice controllo sese invicem convenienter et facile operandi, mutant formam sine pausa et mutare spolas automate. Haec machina est cum facili operatione, alta efficentia et bonitate producti.

| Genus machinae | LHT450/13 | LHT450/11 | LHT450/9 |

| Maximus Diametros Ingressus (mm) | φ8 | φ8 | φ8 |

| Orificium Dia.(mm) | φ1.2-4.0 | φ1.5-4.0 | φ2.1-4.0 |

| Max. numerus formae ferreae | 13 | 11 | 9 |

| Max. velocitas lineae (m/s) | 25 | 22 | 20 |

| Corpus compages | Fusum ferreum | ||

| Transmissio Type | Per rotam acutissime molitam | ||

| Diametros Capstani Velocitatis Fixae (mm) | Diametros Capstani Velocitatis Fixae (mm) | ||

| Delineatio Capstans | φ450 | ||

| Vis motoris principalis(kw) | Tungstenus obductus | ||

| Fixa velocitas capstan motoris (KW) | 280 | ||

| Genus lubricationis | 75 | ||

| Genus lubricationis | Immersionis | ||

| Ad libitum Equipment | 1. Dispositivum continua adolentis 450T 2. Duplex rado colligendi 3. Rotulus 4. WS-1000 colligendi | ||

| In linea Continuus Recalantio Apparatus | ||

| Genus machinae | 450T | 450TB |

| Recalantio Filum Dia. (mm) | ø1.2-3.5 | ø1.2-4.2 |

| Recalantio Voltus(V) | 0-60 | 0-60 |

| Recalantio Currentis(A) | 0-6000A (DC) | 0-5000A (AC) |

| Max. Recalantio Celeritas(m/s) | 25 | |

JCJX-DT21\/100.16 Machina Tractus Filorum Multorum

Unum ex principalibus praesidiis machinae delineandi multifilum est eius altus productivus. Delineando plures filos simul, machina crebro auctiorem exitum praebet quam traditiouales machinae delineandi unifilum. Machinae delineandi multifilum sunt versatiles et possunt tractare varios generes virorum metallicorum et fasciculos filorum, inter quos aes, alumen, et eorum confoederationes.

Diametros output: Fac 0.15-0.5mm filos tenuis

| Genus machinae | DT18/120.4 | DT24/100.16 | DT24/100.20 |

| Tractura Filum Num. | 4 Fila | 16 Fili | 20 Fili |

| Max. Foramen Num. | 18 | 24 | 24 |

| Max. Diametrum Introitus (mm) | ø1.85 | ø2.6 | ø2.6 |

| Orificium Dia.(mm) | ø0.25- Ø0.7 | ø0.16- Ø0.4 | ø0.16- Ø0.4 |

| Tractura Rotulus Diam.(mm) | ø120 | ø100 | ø100 |

| Max. Velocity of Drawing (m/s) | 25 | 30 | 30 |

JCJX-650P Automatica Duplex Torquens Machina

Id ad torsionem fili aeris nudi, fili stannati et fili lacquati quae sunt plus quam 7 fila, Frenum magneticum, quod frenat automaticum quando filum frangitur, tensio adoptat typum freni magnetici pulvis. (PLC control output)

| Genus machinae | JCJX-650P | JCJX-800P | JCJX-1000 |

| Usus | Ad conglobandum 7 fila aeris nudi, fili stannati, fili lacquati. | ||

| Typus controlis | PLC+HMI+Inverter controlis | ||

| Area sectionis torsionis (mm2) | 0.18-6.00 | 2.5-16.00 | 8.00-20.00 |

| Diametrum fili aerei (mm) | φ0.18-Φ1.00 | φ0.50-Φ1.20 | φ0.72-Φ6.0 |

| Torsio pitch(mm) | 11.61-99.04 | 22.51-152.32 | 22.73-173.66 |

| Directio torquens | S vel Z | ||

| Receptura tensio | Tensio Controlatur per Frictio Magnetica | ||

| Maxima Velocitas Axes Principalis (r/min) | 2000 | 1200 | 800 |

| Genus Traversandi | Transversum et distantia possunt adjustari per rota transversa | ||

| Lubricatio Rotuli | Lubricatio olei tenuis, circulatio refrigerans | Lubricans papilla oleo alto temperatura | Lubricans papilla oleo alto temperatura |

| Typus Imbribus&Eximbribus Fusorum | Typus Hydraulicus | ||

| Max. Dia. Fusorum | φ630 | φ800 | φ1000 |

| Unitas Stoppus Automata | Stoppus automatus dum attingit longitudinem praefinitam, et filum fractum intra et extra | ||

| Fregit | Frenum Magneticum | ||

| Motor Power(kw) | 7.5 | 11 | 22 |

| Altitudinis Centrum Axis Principalis (mm) | 850 | 900 | 1100 |

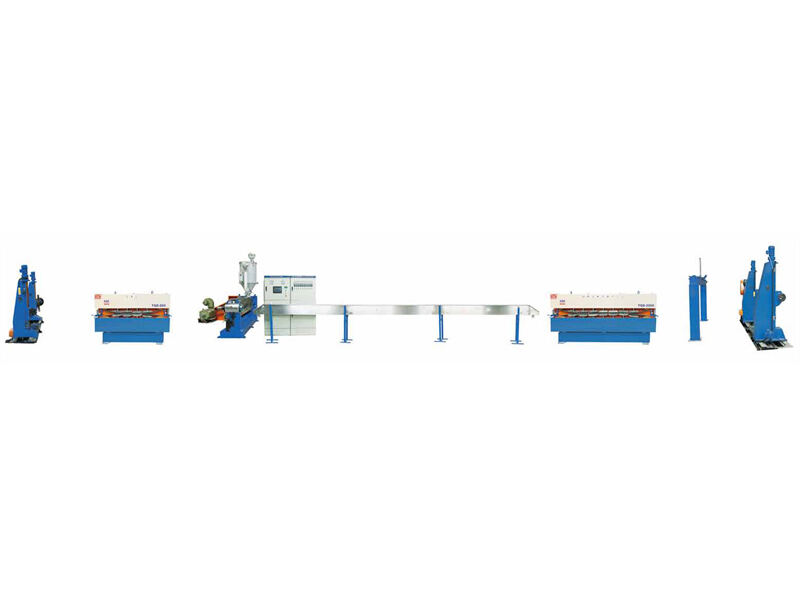

JCJX-70+35 Machina Extrusoria

Designum accurate screw, durabile, sine mucus, non ablatis chrome, color mutat cito, cum magna capacitate, alta qualitate, concentricitas fili est plus quam 90%, cum alta praecisione ±0.03. Cum schermo tactus+PLC control, facilis operatio, magis homogeneus.

1. Usus: adhibetur ad insulandum cablum cum PVC, LDPE, NYLON, TPU.

2. Consistit in linea productionis: emissio, machina principalis, armarium principale, sulcus fixus, tractio, collatio.

3. Partes optionales: caterpillar, machina scintillans, diameter probans laser metrum, LSZH helix, gantry typus collationis et emissionis, axis terminus typus collationis et emissionis.

| Typus | JCJX-30 | JCJX-40 | JCJX-50 | JCJX-60 | JCJX-70 | JCJX-80 | JCJX-90 |

| Diametros Fusi (mm) | ø30 | ø40 | ø50 | ø60 | ø70 | ø80 | ø90 |

| RATIO SCROFAE L\/D | 25:1 | 25:1 | 25:1 | 25:1 | 25:1 | 25:1 | 25:1 |

| Capacitas Extrusionis (kg/h) PVC | 25 | 40 | 80 | 100 | 130 | 200 | 240 |

| Capacitas Extrusionis (kg/h) LDPE | 16 | 20 | 40 | 53 | 86 | 122 | 133 |

| Capacitas Extrusionis (kg/h) PP | 13 | 17 | 34 | 41 | 68 | 96 | 124 |

| Potentia motoris principalis | 5.5 | 7.5 | 11 | 18.5 | 22-37 | 30-55 | 37-75 |

| Summa potentia | 21 | 24 | 28 | 42 | 50 | 65 | 75-113 |

| Diametrus Finitus (mm) | 0.2-1 | 0.4-3 | 0.8-5 | 1-8 | 2-12 | 3-25 | 5-35 |

| MATERIA DIMENSIONIS ROTULI (mm) | 300/400 | 300/500 | 400/630 | 500/630 | 500/630 | 500/630 | 630/800 |

| Vires Solvendi | 2.2 | 3.7 | 3.7 | 3.7 | 3.7 | 5.5/7.5 | 7.5/11 |

| Genus Unitatis Tractandi | Capastan | Capastan | Capastan | Capastan | Capastan | Capastan Caterpillar | Capastan Caterpillar |

| Vires Machinae Tractus | 1.5 | 2.2 | 2.2 | 3.7 | 3.7 | 5.5 | 5.5 |

| Longitudo Accumulatoris (m) | 220 | 220 | 220 | 220 | 220 | 220 | 220 |

| Machina Receptus Dimensus (mm) | 400/500 | 400/630 | 400/630 | 500/630 | 630/800 | 800/1000 | 630/1250 |

| Vires Assumptionis | 2.2 | 2.2 | 2.2 | 2.2 | 3.7 | 3.7 | 5.5 |

| Velocitas Lineae (m/min) | 10-650 | 10-650 | 10-650 | 10-650 | 10-500 | 10-350 | 10-250 |

| Dimensiones(m) (L*W*H) | 20*1.5*2.1 | 20*1.6*2.1 | 20*1.7*2.1 | 20*2.5*2.1 | 25*2.5*2.1 | 25*3.2*2.1 | 30*3.6*2.1 |

| Pondus (T) | 5 | 6 | 8 | 8 | 8.5 | 7-9 | 9-12 |

JCJX-1000 Machina Torsionis Unica Cum Brachio Librato

Convenit ad omnes generis cables datuum, cables communicationum, cables speciales tortos, simul cum centro involucro et involucro laterali completa.

| Exemplum | JCJX-630 | JCJX-800 | JCJX-1000 | JCJX-1250 |

| Diametrum bobinae praeparationis (mm) | φ400-Φ500-Φ630 | |||

| Diametrum bobbinæ receptivæ (mm) | φ630 | φ800 | φ1000 | φ1250 |

| Conveniens diametrum fili (mm) | φ0.6-3.0 | φ1.0-5.0 | ||

| Vis motoris principalis(kw) | 11 | 15 | 15 | 20 |

| Maximus diametrum dispositionis (mm) | φ15 | φ20 | φ25 | φ30 |

| Torsio pitch(mm) | 20-200 | 30-300 | 30-350 | 30-350 |

| Numerus rotationis(r/min) | 1000 | 800 | 600 | 550 |

| Receptura tensio | Pneumatica tensio | |||

| Stilus transeundi | Regulatio continua, secundum velocitatem rotationis fusorum et motum reciprocantem | |||

| Intervallum transeundi(mm) | 2-12 | 3-20 | 3-30 | 3-30 |

| Directio torquens | Directio S aut Z liber descriptio | |||

| Genus involvens | Involventes filum centrali vel laterali involvente | |||

JCJX-90 Machina Extrusoria

Ambitus applicationis: applicatur ad productionem funiculi PVC isolati, praebet tegumentum protectivum filo 2-5 nucleorum et filo plano 2 * 1.5mm2

| Typus | JCJX-30 | JCJX-40 | JCJX-50 | JCJX-60 | JCJX-70 | JCJX-80 | JCJX-90 |

| Diametros Fusi (mm) | ø30 | ø40 | ø50 | ø60 | ø70 | ø80 | ø90 |

| RATIO SCROFAE L\/D | 25:1 | 25:1 | 25:1 | 25:1 | 25:1 | 25:1 | 25:1 |

| Capacitas Extrusionis (kg/h) PVC | 25 | 40 | 80 | 100 | 130 | 200 | 240 |

| Capacitas Extrusionis (kg/h) LDPE | 16 | 20 | 40 | 53 | 86 | 122 | 133 |

| Capacitas Extrusionis (kg/h) PP | 13 | 17 | 34 | 41 | 68 | 96 | 124 |

| Potentia motoris principalis | 5.5 | 7.5 | 11 | 18.5 | 22-37 | 30-55 | 37-75 |

| Summa potentia | 21 | 24 | 28 | 42 | 50 | 65 | 75-113 |

| Diametrus Finitus (mm) | 0.2-1 | 0.4-3 | 0.8-5 | 1-8 | 2-12 | 3-25 | 5-35 |

| MATERIA DIMENSIONIS ROTULI (mm) | 300/400 | 300/500 | 400/630 | 500/630 | 500/630 | 500/630 | 630/800 |

| Vires Solvendi | 2.2 | 3.7 | 3.7 | 3.7 | 3.7 | 5.5/7.5 | 7.5/11 |

| Genus Unitatis Tractandi | Capastan | Capastan | Capastan | Capastan | Capastan | Capastan Caterpillar | Capastan Caterpillar |

| Vires Machinae Tractus | 1.5 | 2.2 | 2.2 | 3.7 | 3.7 | 5.5 | 5.5 |

| Longitudo Accumulatoris (m) | 220 | 220 | 220 | 220 | 220 | 220 | 220 |

| Machina Receptus Dimensus (mm) | 400/500 | 400/630 | 400/630 | 500/630 | 630/800 | 800/1000 | 630/1250 |

| Vires Assumptionis | 2.2 | 2.2 | 2.2 | 2.2 | 3.7 | 3.7 | 5.5 |

| Velocitas Lineae (m/min) | 10-650 | 10-650 | 10-650 | 10-650 | 10-500 | 10-350 | 10-250 |

| Dimensiones(m) (L*W*H) | 20*1.5*2.1 | 20*1.6*2.1 | 20*1.7*2.1 | 20*2.5*2.1 | 25*2.5*2.1 | 25*3.2*2.1 | 30*3.6*2.1 |

| Pondus (T) | 5 | 6 | 8 | 8 | 8.5 | 7-9 | 9-12 |