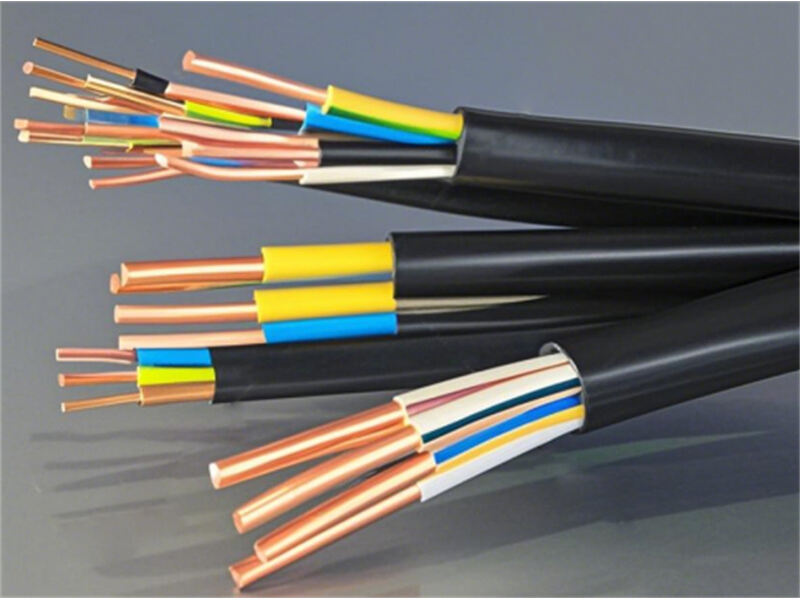

Uzbekistan, as an energy hub in Central Asia, is accelerating the modernization of its power grid and the development of new energy projects. In 2024, our company signed a contract with a customer in Uzbekistan for the complete design of equipment for manufacturing 0.5-6mm ² 2-5 core wires and 2 * 1.5mm ² flat cables, covering the entire process of design, manufacturing, installation, and personnel training.

After preliminary research, formulation of plans, communication and modification, contract signing, equipment production, delivery of machinery, dispatch of engineers for installation and commissioning, the entire process took four months. At present, the customer's factory has started production, and the person in charge of factory coordination has given high praise to Jiacheng's equipment, stating that they will continue to cooperate with Jiacheng in the future.

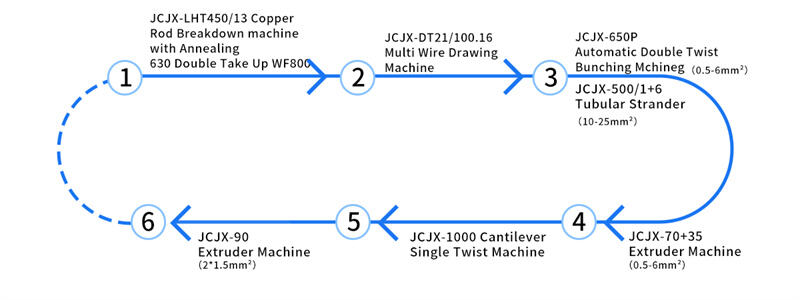

The overall equipment design is as follows:

1.LHT450/13 Copper Rod Breakdown Machine With Annealing Drawing from 8mm copper wire to 1.2-3.5mm

2.JCJX-DT21/100.16 Multi Wire Drawing Machine Produce 0.15-0.5mm fine wires

3.JCJX-650P Automatic Double Twist Bunching Machine Twist 19-84 wires to produce soft twisted conductors of 0.5-6mm² square meters

4.JCJX-70+35 Extruder Machine Insulation extrusion for 0.5-6 square wires

5.JCJX-1000Cantilever Single Twist Machine Stranded 2-5 core insulated wires

6.JCJX-90 Extruder Machine Provide a protective sheath for 2-5 core cable and 2 * 1.5mm2 flat wire

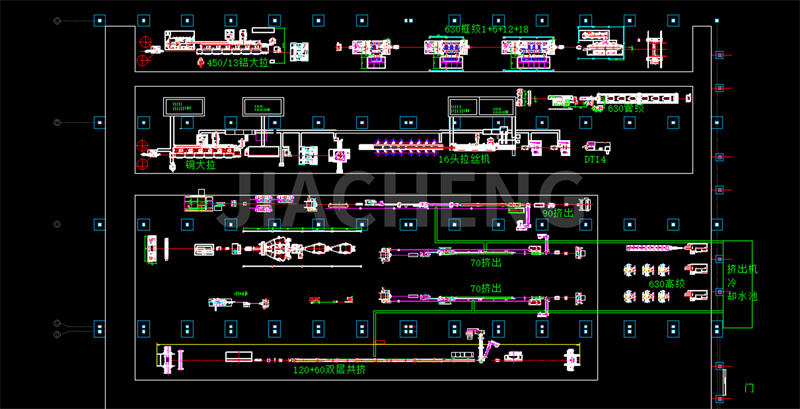

Customer factory planning drawings:

LHT450/13 Copper Rod Breakdown Machine With Annealing

JCJX-LHT450/13 high-speed copper rod breakdown machine is to draw∮8mm ordinary copper rod to∮1.2-3.5mm soft copper wire. The drawing capstans are arranged in a line that is able to work continuously with high drawing speed. The mechanical parts and electrical control match each other and easy to operate, change dies without pause and to change spools automatically. This machine is with the features of easy operation, high efficiency and good quality product.

| Machine Type | LHT450/13 | LHT450/11 | LHT450/9 |

| Max.Inlet Dia.(mm) | φ8 | φ8 | φ8 |

| Outlet Dia.(mm) | φ1.2-4.0 | φ1.5-4.0 | φ2.1-4.0 |

| Max.Die No. | 13 | 11 | 9 |

| Max. line speed(m/s) | 25 | 22 | 20 |

| Body structure | Ironed cast | ||

| Transmission type | By high precision grinding gear | ||

| Fix speed capstan Dia.(mm) | Fix speed capstan Dia.(mm) | ||

| Drawing capstan | φ450 | ||

| Main motor power(KW) | Coated by tungsten | ||

| Fix speed capstan motor(KW) | 280 | ||

| Lubrication type | 75 | ||

| Lubrication type | Immersion | ||

| Optional equipment | 1. 450T continuous annealing device 2. Double rake-up 3. Coiler 4、WS-1000 take-up | ||

| On-line Continous Annealing Device | ||

| Machine Type | 450T | 450TB |

| Annealing Wire Dia. (mm) | Ø1.2-3.5 | Ø1.2-4.2 |

| Annealing Voltage(V) | 0-60 | 0-60 |

| Annealing Current(A) | 0-6000A (DC) | 0-5000A (AC) |

| Max. Annealing Speed(m/s) | 25 | |

JCJX-DT21/100.16 Multi Wire Drawing Machine

One of the key advantages of a multi-wire drawing machine is its high productivity. By drawing multiple wires simultaneously, the machine significantly increases output compared to traditional single-wire drawing machines. Multi-wire drawing machines are versatile and can handle various types of metal rods and wire bundles, including copper, aluminum, and their alloys.

Output diameter: Produce 0.15-0.5mm fine wires

| Machine Type | DT18/120.4 | DT24/100.16 | DT24/100.20 |

| Drawing Wire No. | 4 Wires | 16 Wires | 20 Wires |

| Max. Die No. | 18 | 24 | 24 |

| Max. Inlet Dia.(mm) | Ø1.85 | Ø2.6 | Ø2.6 |

| Outlet Dia.(mm) | Ø0.25- Ø0.7 | Ø0.16- Ø0.4 | Ø0.16- Ø0.4 |

| Drawing Capstan Dia.(mm) | Ø120 | Ø100 | Ø100 |

| Max. Drawing Speed(m/s) | 25 | 30 | 30 |

JCJX-650P Automatic Double Twist Bunching Machine

It is adapt to twist the bare copper wire, tin-coating wire and varnished wire which are more than 7 strands, Magnetic brake, which brake automatic when wire break, tension adopts magnetic powder clutch type.(PLC control output)

| Machine Type | JCJX-650P | JCJX-800P | JCJX-1000 |

| Use | For bunching 7 bare copper, tinned wire,enameled wire | ||

| Control Type | PLC+HMI+Inverter control | ||

| Twisting Section area(mm2) | 0.18-6.00 | 2.5-16.00 | 8.00-20.00 |

| Copper Wire Dia.(mm) | Φ0.18-Φ1.00 | Φ0.50-Φ1.20 | Φ0.72-Φ6.0 |

| Twisting Pitch(mm) | 11.61-99.04 | 22.51-152.32 | 22.73-173.66 |

| Twisting Direction | S or Z | ||

| Take-up Tension | Tension Controlled by magnetic clutch | ||

| Max Main Shaft Speed(r/min) | 2000 | 1200 | 800 |

| Traversing Type | Transverse and distance can be adjusted by bearing transverse | ||

| Bearing Lubrication | Thin oil lubrication, circulation cooling | Lubricating nipple with high temperature oil | Lubricating nipple with high temperature oil |

| Bobbin Loading&Unloading Type | Hydraulic type | ||

| Max. Bobbin Dia. | Φ630 | Φ800 | Φ1000 |

| Auto Stop Unit | Auto stop while reach setting length,and wire broken inside and outside | ||

| Brake | Magnetic brake | ||

| Motor Power(kw) | 7.5 | 11 | 22 |

| Main Shaft Center Height(mm) | 850 | 900 | 1100 |

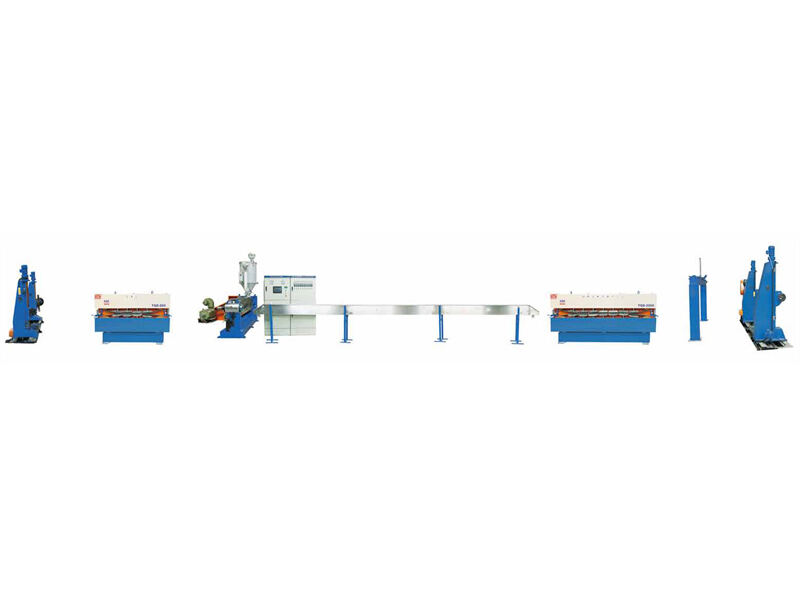

JCJX-70+35 Extruder Machine

Precise design of the screw, durable, non-mucus, not take off chrome, change color quickly, with high capacity, high quality, the concentricity of wire is more than 90%, with high precision ±0.03. With touch screen+PLC control, easy operation, more hommization.

1. Usage: it's used for the insulation of cable with PVC, LDPE,NYLON,TPU.

2. Production line consist: pay off, main machine, main cabinet, fixed trough, traction, take-up.

3. Optional parts: caterpillar, sparkling machine, diameter-testing laser gauge, LSZH screw, gantry type take-up and pay off, end-shaft type take-up and pay off.

| Type | JCJX-30 | JCJX-40 | JCJX-50 | JCJX-60 | JCJX-70 | JCJX-80 | JCJX-90 |

| Screw Dia.(mm) | Ø30 | Ø40 | Ø50 | Ø60 | Ø70 | Ø80 | Ø90 |

| Screw L/D Ratio | 25:1 | 25:1 | 25:1 | 25:1 | 25:1 | 25:1 | 25:1 |

| Extrusion Capacity(kg/h) PVC | 25 | 40 | 80 | 100 | 130 | 200 | 240 |

| Extrusion Capacity(kg/h) LDPE | 16 | 20 | 40 | 53 | 86 | 122 | 133 |

| Extrusion Capacity(kg/h) PP | 13 | 17 | 34 | 41 | 68 | 96 | 124 |

| Main Motor Power | 5.5 | 7.5 | 11 | 18.5 | 22-37 | 30-55 | 37-75 |

| Total Power | 21 | 24 | 28 | 42 | 50 | 65 | 75-113 |

| Finshed Dia.(mm) | 0.2-1 | 0.4-3 | 0.8-5 | 1-8 | 2-12 | 3-25 | 5-35 |

| Pay-off Bobbin Size(mm) | 300/400 | 300/500 | 400/630 | 500/630 | 500/630 | 500/630 | 630/800 |

| Pay-off Power | 2.2 | 3.7 | 3.7 | 3.7 | 3.7 | 5.5/7.5 | 7.5/11 |

| Haul-off Unit Type | Capastan | Capastan | Capastan | Capastan | Capastan | Capastan Caterpillar | Capastan Caterpillar |

| Haul-off Unit Power | 1.5 | 2.2 | 2.2 | 3.7 | 3.7 | 5.5 | 5.5 |

| Accumulater Length(m) | 220 | 220 | 220 | 220 | 220 | 220 | 220 |

| Take-up Bobbin Size(mm) | 400/500 | 400/630 | 400/630 | 500/630 | 630/800 | 800/1000 | 630/1250 |

| Take-up Power | 2.2 | 2.2 | 2.2 | 2.2 | 3.7 | 3.7 | 5.5 |

| Line Speed(m/min) | 10-650 | 10-650 | 10-650 | 10-650 | 10-500 | 10-350 | 10-250 |

| Dimension(m) (L*W*H) | 20*1.5*2.1 | 20*1.6*2.1 | 20*1.7*2.1 | 20*2.5*2.1 | 25*2.5*2.1 | 25*3.2*2.1 | 30*3.6*2.1 |

| Weight(T) | 5 | 6 | 8 | 8 | 8.5 | 7-9 | 9-12 |

JCJX-1000Cantilever Single Twist Machine

It’s suitable for all kinds of data cables, communication cables, special cables twisted, at the same time completed center wrapping and lateral wrapping.

| Model | JCJX-630 | JCJX-800 | JCJX-1000 | JCJX-1250 |

| Pay-off bobbin dia.(mm) | Φ400-Φ500-Φ630 | |||

| Take-up bobbin dia.(mm) | Φ630 | Φ800 | Φ1000 | Φ1250 |

| Applicable wire dia.(mm) | Φ0.6-3.0 | Φ1.0-5.0 | ||

| Main motor power(kw) | 11 | 15 | 15 | 20 |

| Max. lay-up dia.(mm) | Φ15 | Φ20 | Φ25 | Φ30 |

| Twisting pitch(mm) | 20-200 | 30-300 | 30-350 | 30-350 |

| No. of rotate(r/min) | 1000 | 800 | 600 | 550 |

| Take-up tension | Pneumatic tension | |||

| Traversing style | Stepless regulation,according to bobbin rotation speed and reciprocating motion | |||

| Traversing distance(mm) | 2-12 | 3-20 | 3-30 | 3-30 |

| Twisting direction | S or Z Direction free designation | |||

| Wrapping type | Center wire-wrapping or side wrapping | |||

JCJX-90 Extruder Machine

Application scope: apply to the production of PVC insulated cable,provide a protective sheath for 2-5 core cable and 2 * 1.5mm2 flat wire

| Type | JCJX-30 | JCJX-40 | JCJX-50 | JCJX-60 | JCJX-70 | JCJX-80 | JCJX-90 |

| Screw Dia.(mm) | Ø30 | Ø40 | Ø50 | Ø60 | Ø70 | Ø80 | Ø90 |

| Screw L/D Ratio | 25:1 | 25:1 | 25:1 | 25:1 | 25:1 | 25:1 | 25:1 |

| Extrusion Capacity(kg/h) PVC | 25 | 40 | 80 | 100 | 130 | 200 | 240 |

| Extrusion Capacity(kg/h) LDPE | 16 | 20 | 40 | 53 | 86 | 122 | 133 |

| Extrusion Capacity(kg/h) PP | 13 | 17 | 34 | 41 | 68 | 96 | 124 |

| Main Motor Power | 5.5 | 7.5 | 11 | 18.5 | 22-37 | 30-55 | 37-75 |

| Total Power | 21 | 24 | 28 | 42 | 50 | 65 | 75-113 |

| Finshed Dia.(mm) | 0.2-1 | 0.4-3 | 0.8-5 | 1-8 | 2-12 | 3-25 | 5-35 |

| Pay-off Bobbin Size(mm) | 300/400 | 300/500 | 400/630 | 500/630 | 500/630 | 500/630 | 630/800 |

| Pay-off Power | 2.2 | 3.7 | 3.7 | 3.7 | 3.7 | 5.5/7.5 | 7.5/11 |

| Haul-off Unit Type | Capastan | Capastan | Capastan | Capastan | Capastan | Capastan Caterpillar | Capastan Caterpillar |

| Haul-off Unit Power | 1.5 | 2.2 | 2.2 | 3.7 | 3.7 | 5.5 | 5.5 |

| Accumulater Length(m) | 220 | 220 | 220 | 220 | 220 | 220 | 220 |

| Take-up Bobbin Size(mm) | 400/500 | 400/630 | 400/630 | 500/630 | 630/800 | 800/1000 | 630/1250 |

| Take-up Power | 2.2 | 2.2 | 2.2 | 2.2 | 3.7 | 3.7 | 5.5 |

| Line Speed(m/min) | 10-650 | 10-650 | 10-650 | 10-650 | 10-500 | 10-350 | 10-250 |

| Dimension(m) (L*W*H) | 20*1.5*2.1 | 20*1.6*2.1 | 20*1.7*2.1 | 20*2.5*2.1 | 25*2.5*2.1 | 25*3.2*2.1 | 30*3.6*2.1 |

| Weight(T) | 5 | 6 | 8 | 8 | 8.5 | 7-9 | 9-12 |