What is Wire Extrusion?

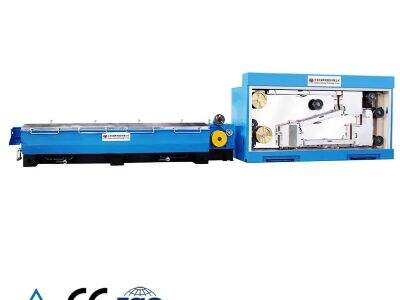

Wire extrusion is what happens when we take such materials, such as plastic or metal, and force it through a machine to produce wires. It is like squeezing toothpaste from a tube. We make wires that can be used for electronics, cables and all sorts of stuff.’ To operate correctly our wire extrusion machine we need to learn how it works.EXTRUSION MACHINES FOR WIREFRAMES, TUBES, PROFILESMade in Italy since 1983 Looking for a product?

To Optimize Settings for Machine:

To make our wire extrusion machine can run well, we must adjust the settings of our machine. That includes ensuring the temperature is perfect, the machine is moving at the right speed and that the pressure is good for the material we are using. By applying these modification, we continuously produce high-quality wires.

Well-Maintained Machine Condition:

Like your car needs regular oil changes to perform well, our wire extrusion machine also require some regular maintenance and care as well. We don’t allow the machine to break down, but maintain it and keep it clean and oiled instead. This allows us to make more wires rapidly, and keep our customers happy.

Quality Materials and Tools:

The best wires require the best materials and best tools. This in turn means seeing to it that we purchase high-quality plastic or metal for our machine. We are also able to produce strong and durable wires by the used of the best materials. And we have good tools to do that, too, cutters and molds and other equipment that will help us make great wires that will meet our customers’ needs.

Expert Techniques for Speed and Accuracy:

To form wires quickly and precisely, we must employ special methods. That requires having trained employees who know how to install the machine and repair it in case of a malfunction. We can make our wires faster and more exact by employing these tried and true methods. It will help us win over our rivals.