Редовно почистване и смазване:

За да се осигури ефективната работа на вашата Машина за чертане на жица , трябва да я почиствате и смазвате често. Машината може да се покрие с мръсотия и прах, а отпадъците могат да намалят ефективността ѝ. Избършете я с мека кърпа, за да премахнете мръсотията и мазнините. Уверете се, че се консултирате с ръководството на машината за конкретните ѝ изисквания. Нанасянето на смазка върху подвижните части на машината ще помогне за предотвратяване на триенето и осигуряване на правилната ѝ работа.

Проверка и подмяна на износени части:

Поради износване, компоненти на вашата Машина за теглене на много жили се износват след известно време. Трябва да се отбележи, че машината трябва да се проверява за износване и повреди на регулярни интервали. Проверете за отпуснати или повредени компоненти и ги заменяйте при необходимост. Гореспоменатите стъпки ще предпазят машината от допълнителни повреди и ще помогнат за поддържането на ефективната работа. Ако не сте сигурни как да демонтирате дадена част, обърнете се към ръководството за употреба на машината или потърсете съвет от специалист.

Контрол на настройките на натоварване и скорост:

Натоварването и скоростта на вашата машина за теглене на жица имат значение за правилното ѝ функциониране. Тези настройки трябва да се проверяват и променят при нужда. Ако натоварването е твърде голямо или твърде слабо, може да доведе до счупена жица или загуба на нейната форма. Също така, ако скоростта е твърде висока или ниска, производството на жицата може да бъде от лошо качество. Като следите тези настройки и правите корекции при нужда, можете да избегнете евентуални проблеми и да поддържате машината за теглене на жица в оптимално състояние.

Обучение на операторите за правилната употреба:

Трябва да се уверите, че всеки, който ще използва машината за влакнодърпане, знае как правилно да я използва. Това е важно не само за предотвратяване на инциденти, но и за използване на машината с максимална ефективност. Уверете се, че операторите са запознати с почистването и смазването на машината, проверката за износване, както и с настройките на натиска и скоростта. Подходящо обучение ще помогне за удължаване на живота на машината и подобряване на общата ѝ производителност.

Внедряване на график за рутинно поддръжка:

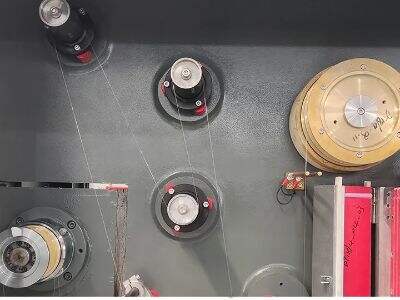

Вижте как изглежда вашият Машина за чертане на жица Само по себе си е разбираемо, че почистването, смазването, проверката на износване на механизма на машината и обучението са част от отговора за колебанието в производителността на машината, но трябва да се има предвид, че операторите трябва да развият редовен модел на поддръжка. Тази програма трябва да показва кога определени дейности трябва да се изпълняват, например кога да се взема проба от течността или кога да се сменят компонентите. С редовна поддръжка можете да следите изискванията на машината и/или да отстранявате проблеми, преди те да се превърнат в по-сериозни въпроси. Това ще гарантира, че вашата машина за теглене на жица няма да се развали или да се повреди в продължение на много години напред.